Manufacturer of concrete prefabrication

molds and specific formworks for construction

CUSTOM

MANUFACTURING

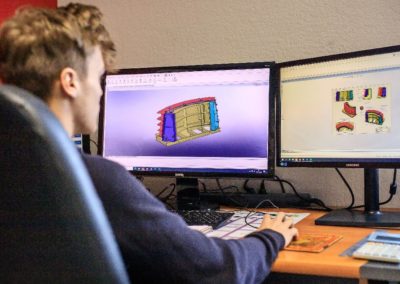

Design Office

3D Design

FRENCH

MANUFACTURER

![]()

CE Certification

THE

KNOW-HOW

a dozen

boilermakers

ON-SITE

INTERVENTION

Commissioning

Maintenance

The different types of concrete pieces manufactured with our molds:

We manufacture for :

Building construction

Beams, …

Architectural concrete parts

Civil engineering

UHPC parts

Sanitation

Environment

Electrical distribution substations

>> Prefabrication molds

Technical piece molds

Civil engineering molds

UHPFRC molds

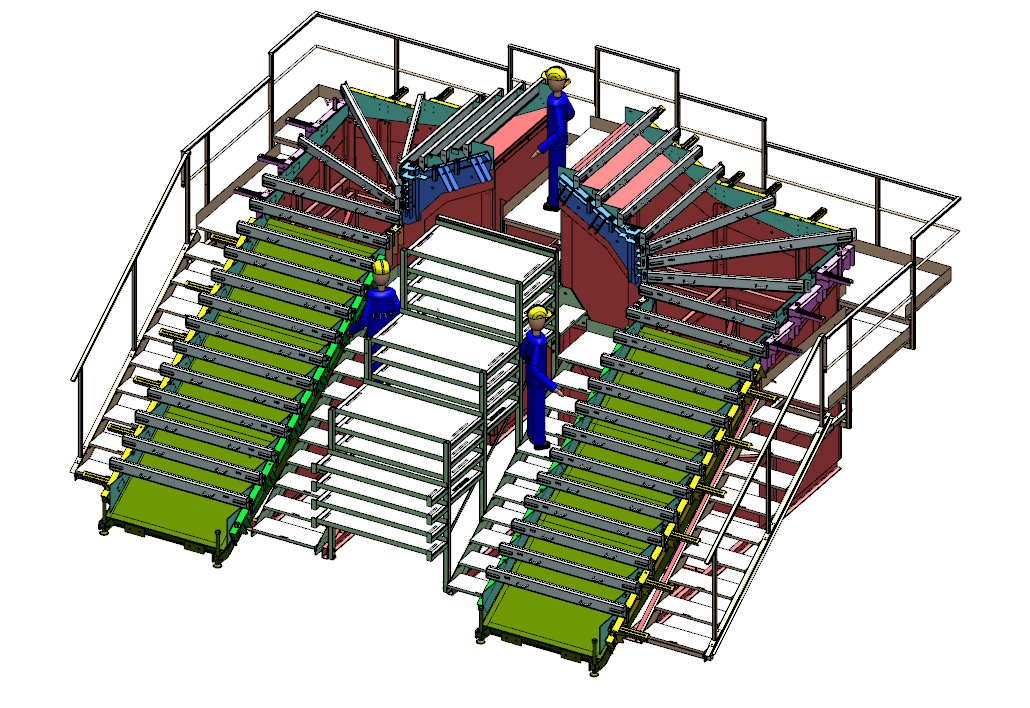

Traveling prefabrication molds

>> Concrete formwork

Prefab table

Precast slab bench

Bridge deck

Bridge piers

Vaults

Beams

>> Special boilermaking

Footbridges

Guardrails

Lifting beams

Transport carts

News :

We once again contributed to the construction of a UHPC footbridge.

CTVS has once again contributed to the construction of an unusual UHPC footbridge in Switzerland's Valais canton, in collaboration with ELEMENT SA in Tafers. The over 70-meter-long, 200-ton footbridge is made up of 23 prefabricated elements produced at the ELEMENT...

Nice diversification for CTVS with this equipment which will soon leave our workshop for a German customer.

2 motorized trucks, radio-controlled. Designed and manufactured by our teams to transport elements weighing up to 50 tons. Product plus: hydraulic transmission to limit deck height. Information : - Height 2.6 m - Length: 2 x 6.5 m (single or tandem operation) -...

Instant mold release: non-draining well nozzles

After a long series of "delayed demolding" concrete molds, a fine example of molds designed and manufactured by CTVS for "immediate demolding". Non-draining / draining well nozzles in D1000. A fine project efficiently managed by our Design Office and manufacturing...

Two carts and a gangway mold

Customized prefabrication molds for concrete castings

We design, manufacture, market and install special boiler-making machines for the concrete parts or prefabrication prefabrication molds prefabrication molds.

For our customers: prefabrication plants of concrete parts, we provide solutions that enable you to manufacture parts to your quality and cost standards.

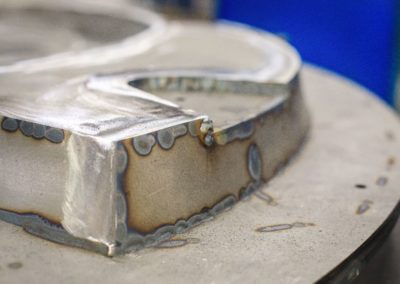

All our molds are made of steel with optional inserts in other materials.

All our moulds are custom-made

All molds designed by our metalwork shop are custom-made. Developed from your concrete plan, we design your equipment according to your requirements, specific production constraints, and your industrial environment. Each mold is specifically designed and manufactured to meet your needs.

All our molds are designed in 3D, enabling us to handle all shapes, including non-developable surfaces.

Some tools designed by CTVS are special machines for manufacturing concrete parts. They incorporate various peripheral/related techniques to metalwork with hydraulics (movement and clamping), concrete curing (electric or steam), vibration, automation for cycle management and traceability.

Staircase mold plan

on-site equipment modifications

On-site commissioning of precast molds

CTVS is able to offer a comprehensive service from validation of the first part, start-up, equipment assembly on the customer’s site and staff training.

Maintenance of concrete molds

We are able to perform all maintenance operations in our workshops or on-site (mold bottom refurbishment, modification, restoration…).

When returning your molds proves too complicated, our technicians can also intervene on-site to make modifications as quickly as possible.

We can also supplement your equipment with “accessories” necessitated by new requirements (corner cheeks, end pieces, reservations…).

Our customers

-Concrete prefabrication plants and construction sites

We mainly supply prefabrication plants as well as construction sites for prefabrication.

>> Civil engineering: stadiums, bridges

>> Buildings

>> Architectural works of art.

>> Freiburg im Breisgau, Lucerne, Karlsruhe stadiums

>> Construction majors: Bouygues, Eiffage, Vinci …

We also supply other industrial equipment for precast concrete plants: carts, conveyors, turnersfor handling the concrete parts produced.

CTVS moulds can be designed for 2 demoulding processes:

>> Instant demolding process

>> Delayed demolding process

Moulds for architectural concrete :

one of our specialties.

The purpose of an architectural concrete part is to contribute to the structure of the building… With exceptional facing quality.

Because of the technical difficulties involved, the manufacture of prefabrication molds for architectural parts is one of CTVS’s specialties.

These parts, and therefore the moulds used to produce them, generally have complex geometric shapes with double curvatures, variable cross-sections and twisting movements. It’s a highly technical job for craftsmen, requiring considerable boiler-making know-how.

Design office, mold design

The “design office team” consists of several project managers, we work with SolidWorks software. This allows us to successfully carry out multiple prefabrication mold manufacturing projects simultaneously.

We are able to manage projects in French, German, and English from a commercial, technical, and administrative point of view.

With their skills and experience, the design office members are sources of proposals to offer you the most effective solutions tailored to your needs.

The design plans developed by CTVS’s design office are saved on a secure server. CTVS is able to evolve the molds according to the product’s lifecycle based on customer needs and make modifications on-site.

Highlights

>> Rigor in project monitoring

>> Sensitivity to turnkey solutions

>> Experience

The workshop

We have a dozen boilermakers capable of making all the parts.

Highlights :

>> Experience

>> Know-how

>> Adaptability to new situations

Administrative

An administrative manager, perfectly bilingual in German, enables us to offer the same customer service in French and German.

Philippe Bachelet CEO of CTVS :

>> Mechanical Engineering Engineer

>> Postgraduate degree in Management

>> Several years’ experience abroad in organizations with 10 to 250 employees

Philippe BACHELET, what is your background?

After 20 years of industrial experience as an employee, holding various technical and managerial positions, I wanted to become independent and set up my own business.

In 2008, I chose CTVS because it had real technical know-how, a good reputation in a niche market, and manufactured clean products.

My industrial experience has enabled me to capitalize on technical know-how, modernize certain areas of the company (CAD, laser cutting) and develop exports.

What do you like about your work?

To be able to carry out technical projects from design to commissioning in a French and international environment.

I enjoy challenges, new projects, new technical difficulties, and new destinations. A company must move forward and progress, which is what the entire team strives to do at CTVS.